Contract Development and Manufacturing Organization

- Home

- CMO

CDMO & CMO

Contract Development Manufacturing Organization (CDMO) & Contract Manufacturing Organization (CMO) Services

The R&D pipeline for new drugs has changed considerably over the past decade.

Once dominated by big pharma and small molecules, today’s pipeline is increasingly populated with small and emerging biotech companies developing large molecules, or biologics, which now make up nearly 40% of the active R&D pipeline globally. As scientific advancement in biopharmaceuticals continues to rise, so will the market. The global biological market size is expected to reach $750 billion in 2028 — up from the $285 billion biologics revenues seen in 2020. This rapid and continual growth has created a demand for therapeutics, expanding indications for biologics, and the growing portfolios of biologics.

Biologics are mainly used for treatment of conditions such as cancer, infectious, ophthalmic, anemia and autoimmune diseases and the current success rate is encouraging bio-pharmaceutical players to invest in research and development of biologics on large scale. While these projections are good news for patients and for makers of bio therapies, growth always comes with new challenges. In this case, the industry must learn how to deploy efficient, flexible-modular manufacturing technologies that can respond to upstream and downstream variables. These variables include the proliferation of new biologics, rapid shifts in volumetric requirements, and improvements in cell and bacterial culture strategies.

MPTxpress development comprises the activites that help create a series of steps of steps to produce a biomolecule – a antibody fragment, recombinant protein, recombinant enzyme, plasmid DNA, Viral Vector, or other product that comes from a biological origin.

MPTxpress process is well positioned to offer tangible benefits such as modular batch size, lower operating cost, and faster turnaround and reduced capital investment. We draw on our manufacturing and quality expertise to design Bioprocesses that include optimization and validation of cell line development, upstream and downstream steps processes at scale.

MPTxpress enables us to produce biologics on a rapid, reliable and repeatable scale-up.

CDMO & CMO

cGMP Biologic Development and Manufacturing

MicroProtein Technologies Inc, routinely performs upstream and downstream development and optimization studies for our clients, this is a critical step towards efficient design of GMP-compliant manufacturing processes. We specialize in downstream techniques that outperform competitors in terms of minimizing processing time and formulating methods tailored to each individual molecule, that enable us greater yields with high quality purity and activity.

MicroProtein Technologies Inc, CRO and CDMO services

MicroProtein Technologies (MPT) is prominent in providing CRO and CDMO services for the biopharmaceutical industry include: providing specialized services to Bio-pharmaceutical companies for large-scale recombinant protein expression and protein purification from inclusion bodies, MPT has developed a novel refolding technologies to improve protein yield and quality, offering services on process optimization, and developing proprietary processes to enhance the refolding process; leveraging the cost-effectiveness of MPTxpression systems while overcoming the challenge of inclusion body formation to produce high-value therapeutic proteins.

- Cost-effectiveness of MPTxpression systems: E. coli is a widely used host organism for protein production due to its fast growth rate and relatively low cost.

- Scale-up capabilities: Ability to transition from small-scale laboratory experiments to large-scale production processes.

- Growing demand for biopharmaceuticals: Increasing need for recombinant proteins for therapeutic applications, driving the development of efficient protein production methods.

- Technical expertise: Deep understanding of protein biochemistry, molecular biology, and protein purification techniques, especially related to inclusion body processing.

- Challenges of inclusion body formation: Majority of recombinant proteins expressed in E. coli form inclusion bodies, creating a need for robust solubilizing and refolding technologies.

- Quality control measures: Strict adherence to regulatory standards for biopharmaceutical production.

- Offering custom refolding and purification services to Bio-pharmaceutical companies who need to produce recombinant proteins from inclusion bodies, especially for early-stage development to process scale production runs.

- Expertise in optimizing refolding conditions for specific proteins, including the selection of appropriate solubilizing and refolding kinetics.

- Developing innovative methods for mild solubilization of inclusion bodies, potentially using novel techniques to improve protein yield and activity.

- Process optimization:

- Providing expertise in identifying bottlenecks in existing refolding processes and implementing improvements to increase efficiency and reduce costs.

- Analyzing protein stability, aggregation propensity, and developing strategies to mitigate these issues during refolding.

Formulation development:

- Creating specialized formulations for solubilization and refolding, including stabilizing additives to minimize protein aggregation and improve product stability.

- Researching novel delivery systems for refolded proteins to enhance their therapeutic efficacy.

MicroProtein Technologies (MPT), your premier partner in Contract Research Organization (CRO) and Contract Development and Manufacturing Organization (CDMO) services for the biopharmaceutical industry. Our expertise lies in;

- Specialized Services for Bio-Pharmaceutical Companies:

- Large-Scale Recombinant Protein Expression and Purification: Utilizing innovative refolding technologies to enhance protein yield and quality.

- Process Optimization: Streamlining processes to increase efficiency and reduce costs.

- Proprietary Techniques: Developing cutting-edge methods to overcome challenges in protein refolding.

Key Aspects of Our Services

Contract Manufacturing Services

- Cost-Effective Systems: Leveraging the MPTxpression system for economical production using E. coli, known for its rapid growth and low cost.

- Scale-Up Capabilities: Seamlessly transitioning from laboratory-scale to large-scale production.

- Growing Demand for Biopharmaceuticals: Meeting the increasing need for therapeutic recombinant proteins with efficient production methods.

- Technical Expertise: Proficient in protein biochemistry, molecular biology, and purification techniques, with a focus on inclusion body processing.

- Quality Control: Adhering to stringent regulatory standards for biopharmaceutical production.

- Custom Refolding and Purification Services:

- Early-Stage Development to Scale Production: Tailored services for bio-pharmaceutical companies to produce high-value therapeutic proteins.

- Optimization of Refolding Conditions: Expertise in selecting appropriate solubilizing and refolding kinetics for specific proteins.

- Innovative Solubilization Methods: Developing mild techniques to improve protein yield and activity.

- Process Optimization:

- Bottleneck Identification and Improvement: Enhancing existing processes to increase efficiency and reduce costs.

- Protein Stability and Aggregation Analysis: Developing strategies to mitigate stability and aggregation issues during refolding.

- Formulation Development:

- Specialized Formulations for Solubilization and Refolding: Including stabilizing additives to minimize protein aggregation and improve product stability.

- Novel Delivery Systems: Researching innovative delivery methods to enhance the therapeutic efficacy of refolded proteins.

Why Choose MicroProtein Technologies?

- Cutting-edge innovation and proprietary technologies

- Deep industry expertise and technical proficiency

- Commitment to quality and regulatory compliance

- Tailored solutions to meet your specific needs

Market Drivers for this Business Opportunity

- Growing demand for biopharmaceuticals: Increasing need for recombinant proteins for therapeutic applications, driving the development of efficient protein production methods.

- Cost-effectiveness of MPTxpression systems: E. coli is a widely used host organism for protein production due to its fast growth rate and relatively low cost.

- Challenges of inclusion body formation: Many recombinant proteins expressed in E. coli form inclusion bodies, creating a need for robust solubilizing and refolding technologies.

- Technical expertise: Deep understanding of protein biochemistry, molecular biology, and protein purification techniques, especially related to inclusion body processing.

- Scale-up capabilities: Ability to transition from small-scale laboratory experiments to large-scale production processes.

- Quality control measures: Strict adherence to regulatory standards for biopharmaceutical production.

Protein Purification and Bulk Fill

MicroProtein Technologies has experience with a wide range of protein purification capabilities to meet client’s GMP production needs. Protein purification areas at MicroProtein Technologies are segregated and customized with equipment to meet the requirements of client’s process. Protein purification personnel at MicroProtein Technologies are experts with protein refolding, multiple chromatography techniques, tangential flow filtration, lyophilization, and bulk drug substance filling.

Microbial Cell Banking

MicroProtein Technologies Biologics manufactures and cryo-stores Working and Master Cell Banks to support current and future upstream and downstream requirements. Microbial Cell Banks are cryo-stored in the vapor phase of liquid nitrogen freezers. MicroProtein Technologies manages and coordinates all required testing per ICH and FDA guidelines.

MPT has experience with modular MPTxpress of E.coli. MPTxpress processes are demonstrated in process development and scaled-up for GMP in our facility.

Validation

We have successfully and consistently produced multi-gram quantities of recombinant proteins, including candidate biosimilars: somatropin (rHGH), granulocyte-colony stimulating factor (G-CSF), erythropoietin (EPO) and human interferon beta (rINF-β); also epidermal growth factor (rEGF) and nerve growth factor (rNGF); and large quantities of Proteins A, G and A/G for 3rd party manufacture of affinity resins. MPT has verified the structure and function of many of these proteins, including biological activity confirmed by third party testing in tissue culture and animal models.

CRO and CDMO projects performed at MicroProtein Technologies Inc.

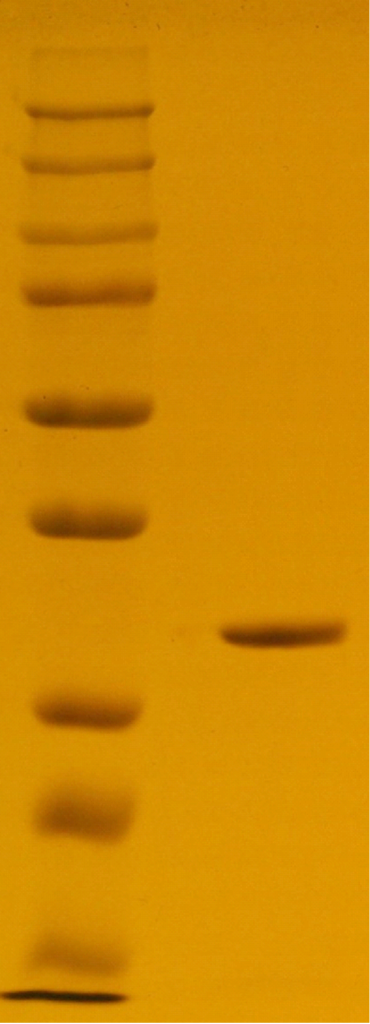

G5: 1.5ug & 2.0ug of recombinant human TGFbeta

Lane 2.) 1.5ug TGFbeta Non-reducing condition. TGFb resolved at 12.8KDa

Lane 3.) 2.0ug of TGFbeta Non-reducing condition, resolved at 12.8KDa.

Both Lane 2 & 3 contain a dimerization of TGFbeta molecule, which resolves at around double TGFb M.W. near 25KDa.

Our Clients

We Serve All Over The World

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec vel dignissim lectus. Pellentesque et scelerisque nunc. Sed vel ipsum auctor, iaculis arcu quis, posuere duiuis condimentum.